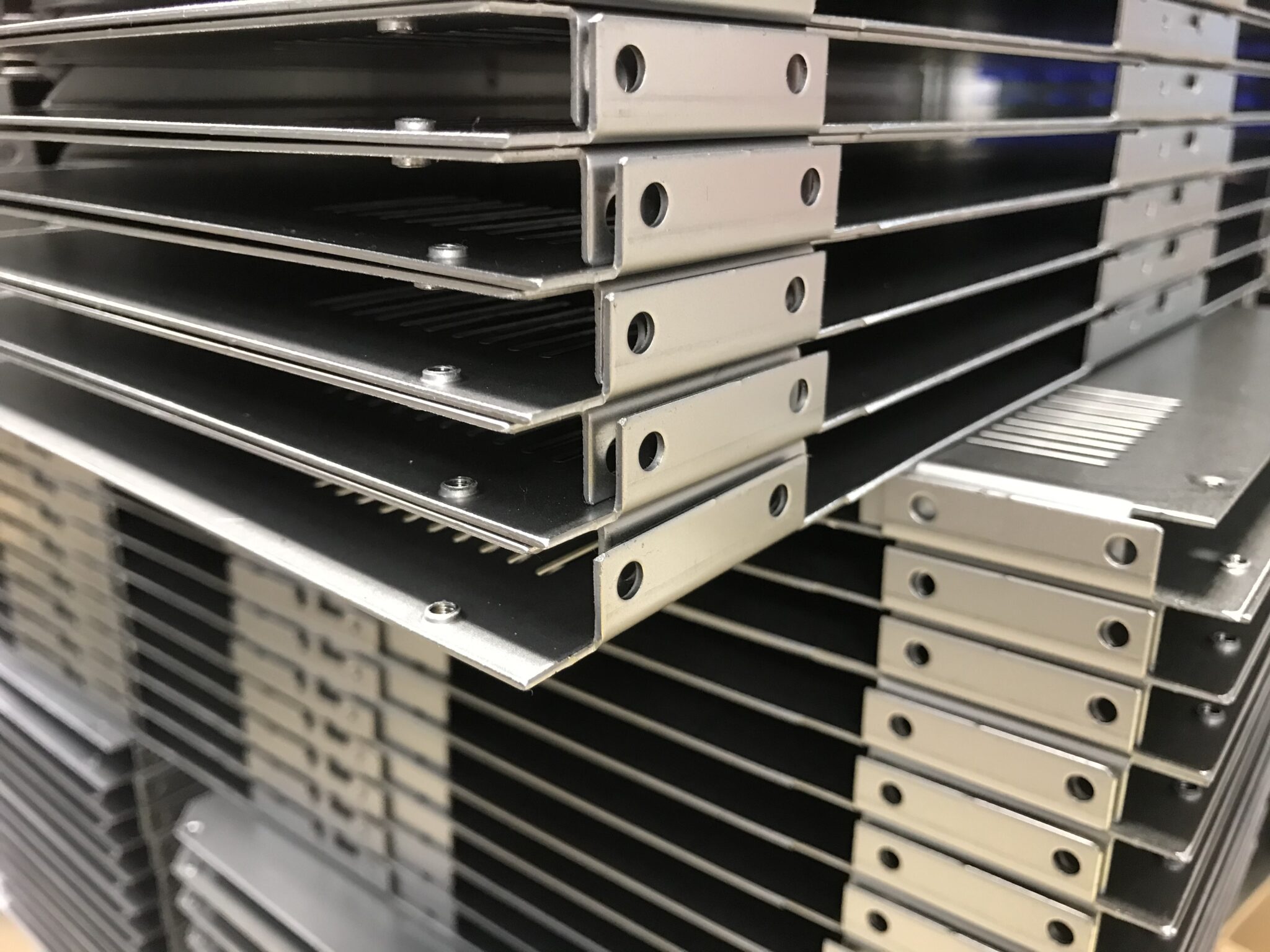

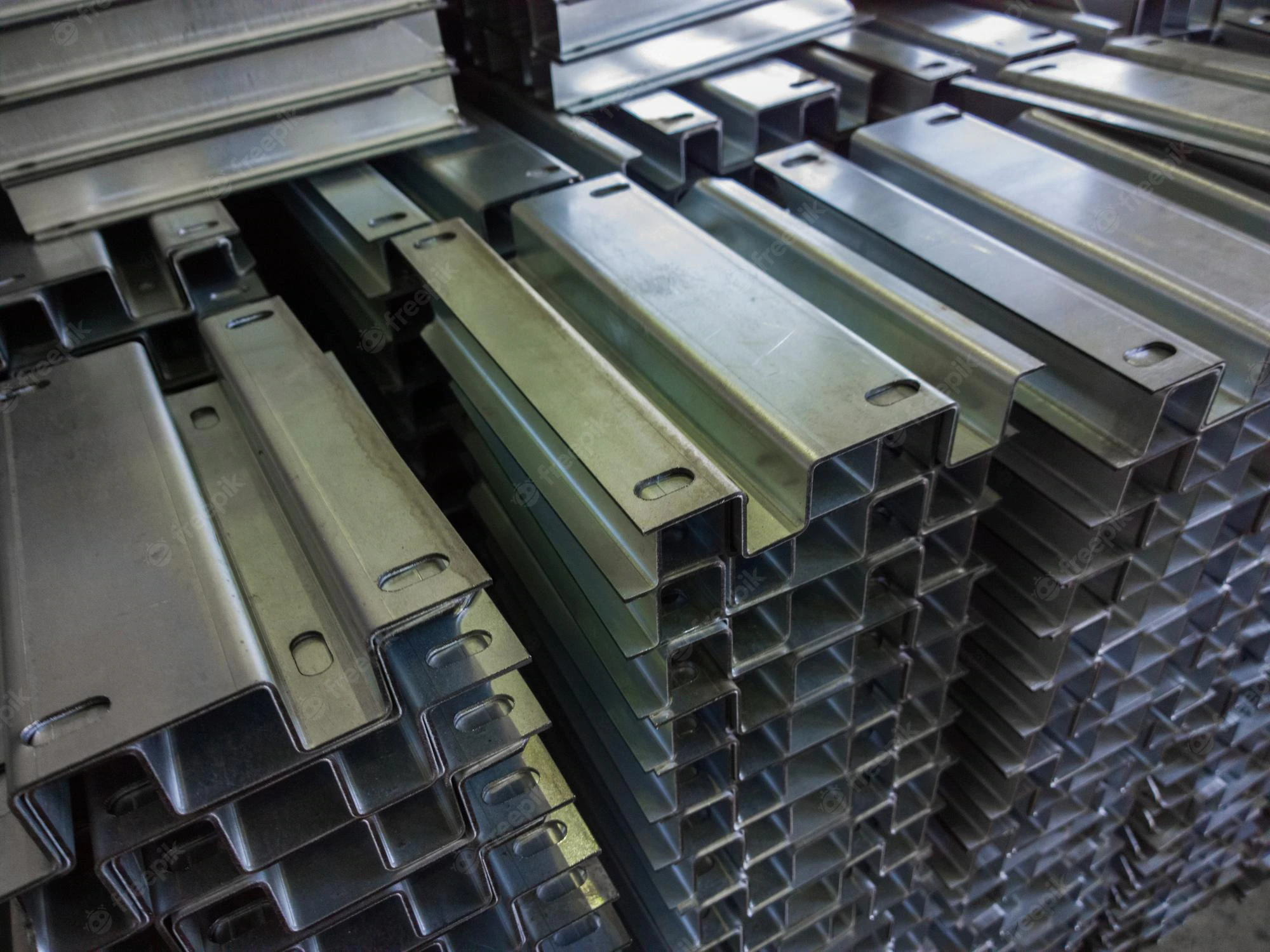

Novelty Structures is an experienced fabricator of Sheet Metal Bending Services for

Carbon Steel, Galvanized Steel, Stainless Steel and Alumunium.

What is metal bending ?

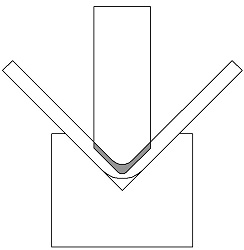

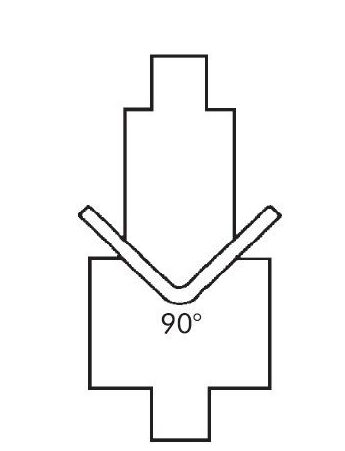

Metal bending is one of the most common metal fabrication operation. The sheet metal bending process involves applying a force to a sheet metal part to change its geometry. This force causes stress on the sheet metal beyond its yield strength and permanent physically deform without breaking or failing.

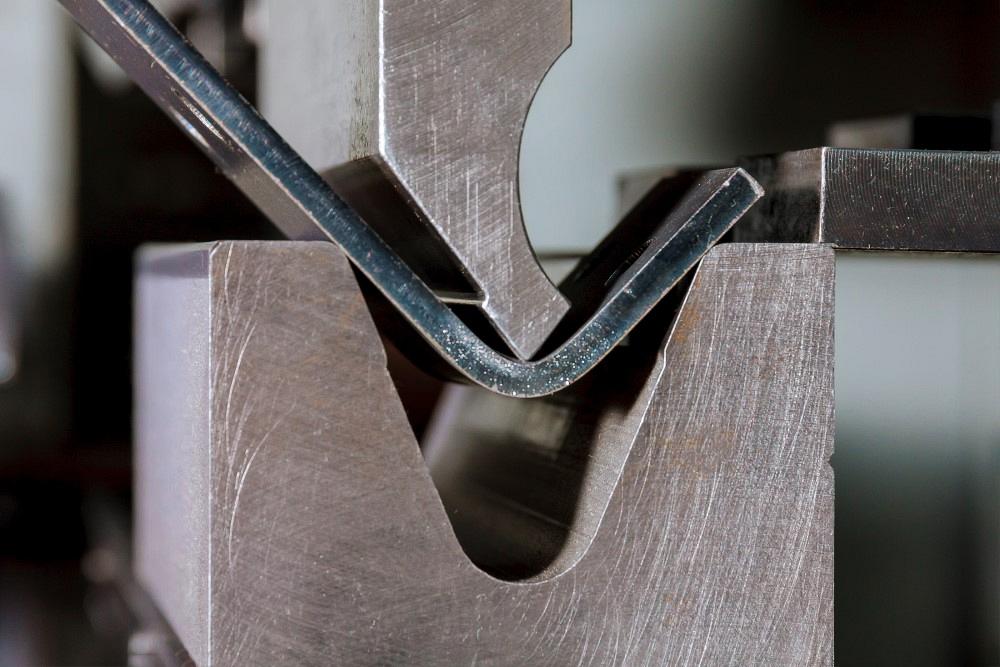

The press brake is a commonly used equipment for sheet metal fabrications. It works by lowering a mould onto a sheet metal work piece positioned on a die, creating the desired form.

The formed bend is dependent upon the tools used, the material yield strength and the material thickness. Setting up a bending operation accurately requires knowledge in the tooling, material, forces and the sequence of the different steps so it requires a skilled operator.

Metal Bending Types

Evolution of Press Brakes

A press brake is a machine that bends sheet metal into predetermined forms.

Guide to Accurate Sheet Bending

Common Defects

Bending Different Metals

Challanges in Metal Bending

How can we help you ?

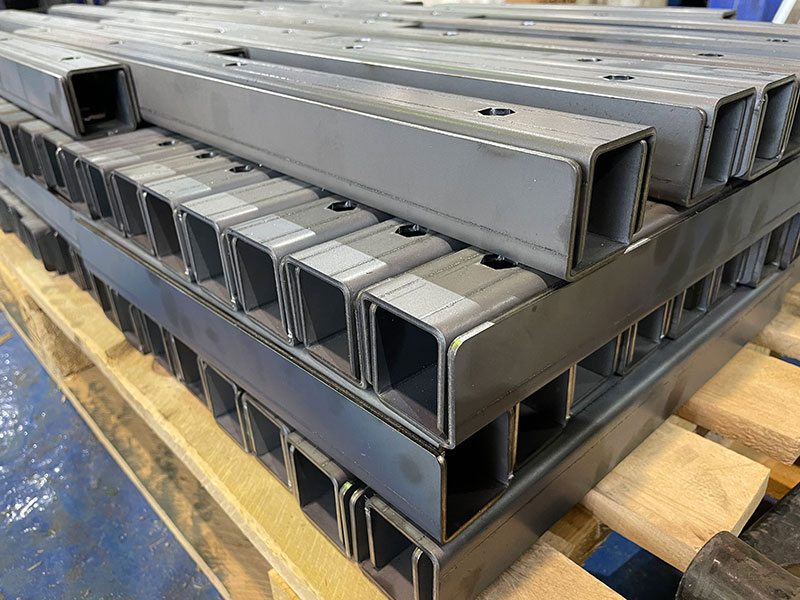

Sheet Metal Bending is a major Metal Fabrication method and its success depends on the careful selection of contractors.

Novelty Structures stands out as a reliable partner in providing High-Quality Metal Bending Services tailored to demanding industrial needs.

FAQ

Recommended Blog Articles

Novelty Structures offers Contract Manufacturing and Fabrication Services through our facilities in Turkey. [...]

Novelty Steel provides a comprehensive set of steel bending services for various industries and [...]

Sheet Metal Fabrication Services for Carbon, Galvanized, Stainless Steel and Aluminium [...]

Novelty Structures is an Experienced Stainless Steel Fabricator with its exceptional Manufacturing Capabilities & [...]

Gallery