Novelty Structures fabricate Steel Buildings, Steel Warehouses, Steel Hangars, Multi Floor Structures and Steel Halls.

What is a Steel Building?

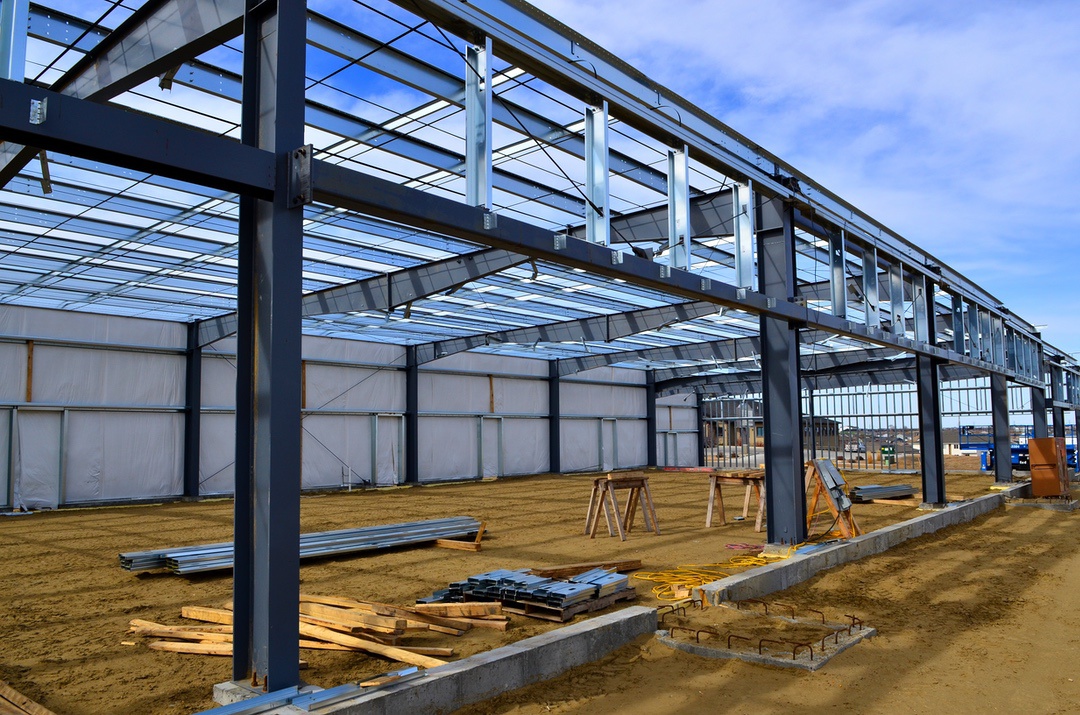

A steel building system is a system designed by special steel engineers according to the building codes and regulations.

Factory-trained professionals manufacture each part of the load bearing frames according to the exact production drawings. Fabricators cut, shape, weld, drill, punch, paint, and mark each part for traceability and fast erection.

Primary Components

Secondary Components

How can we help you ?

Novelty Steel is an experienced fabricator of steel buildings with a proven track record. Novelty Steel has completed the delivery of dozens of steel buildings all around the globe.

With vast CNC Machinery Park and experienced engineering team, Novelty Steel produces bespoke steel buildings according to the EN 1090-2 European Norms.